Guardrail systems used for roofing work may be an effective way to manage some of the risks of working at heights. Roofing work involves a variety of tasks that potentially expose persons to the risk of falls both through and from the edge of the roof structure. Physical edge protection should be provided for all roofing works, so far as is reasonably practicable.

The effectiveness of a guardrail system depends on:

- appropriate design

- manufacture in accordance with the designer's specifications

- test and examination after manufacture

- instructions supporting use and maintenance of the system

- correct installation by a competent person

- appropriate use.

Guardrail systems

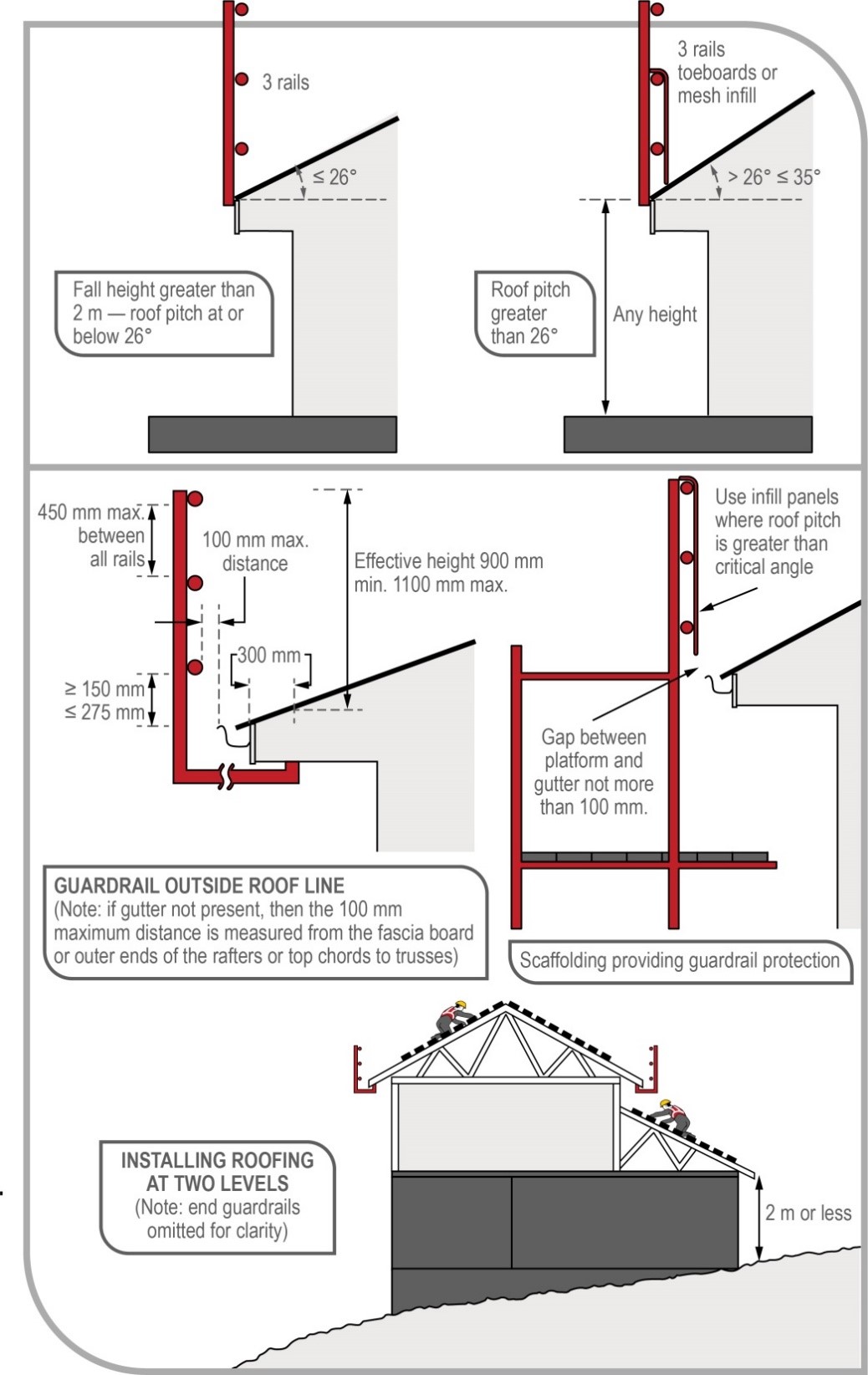

Guardrail systems should include:

- top, mid and bottom rails or toe-boards.

- where toe-boards are used in place of bottom rails they should be able to withstand the likely impact loads.

- toe-boards or mesh infill to prevent tools, materials or debris falling from the roof, unless a 2 metre no go zone has been established to prevent people entering the area below

- a clear gap between rails not exceeding 450 mm. The clear distance between a mid-rail and a toe-board or bottom rail should not exceed 275 mm

- no gap between the roof edge, including the gutter, and a guardrail located outside the roof line exceeding 100 mm

- a clear distance between the roof cladding and the bottom rail of not less than 150 mm and not greater than 275 mm

- an effective guardrail height above the roof surface of not less than 900 mm (for roofs with a pitch over 10 degrees the effective height should be measured from a point 300 mm inside the roof edge)

- infill panels where the pitch of the roof exceeds 26 degrees.

For further information about the protection components, refer to AS/NZS 4994 (set): Temporary edge protection.

Critical angle

The pitch of the roof is one of the key risk factors to be considered when determining the type of risk control measures to be put in place for roofing work. Builders and subcontractors should determine the critical angle as part of their risk assessment.

The critical angle must be below the angle at which roof workers may reasonably be able to work and walk across the roof.

The critical angle must not be greater than:

- 26 degrees, or

- 10 degrees where the roof is slippery or conditions may make the roof slippery.

The critical angle may need to be reduced in the presence of fully glazed and wet tiles.

Access and exit

Workers must have a safe access and exit point when carrying out work on the roof. Depending on the edge protection system being used, you should ensure that:

- people are able to access the roof through the roof edge protection without having to climb over the top rail or mid-rail

- access ladders are secured against movement

- where a platform is located more than 500 mm below the roof edge, additional means of access to the roof is provided

- where an elevator, hoist or similar is used it is installed so that materials can be received at the roof level.

Health and safety obligations

Designers, manufacturers, suppliers and installers all have obligations for the guardrail system that is supplied. Users of the system, including the principal contractor, employers, self-employed persons and workers also have obligations for how it is used and maintained.

Designers

Designers are to ensure that:

- the system is designed to be without risks to a person’s health and safety when used properly

- the design, if given to someone else to use, is accompanied by information about the way the plant is to be used to ensure health and safety.

The designer should consider:

- the type of structures the system may be attached to

- the loads that may be applied if a worker falls against the guardrails.

Manufacturers

Manufacturers have an obligation to ensure that:

- the system is manufactured to be without risks to a person’s health and safety when used properly

- the system, when manufactured, is tested and examined to ensure it will be safe when used properly

- the system, when supplied to another person, is accompanied by information about the way it is to be used to ensure the health and safety of users.

Suppliers

Suppliers have an obligation to either:

- examine and test the system to ensure it is without risks to a person’s health and safety when used properly, or

- ensure the manufacturer has given an assurance that the system has been examined and tested to ensure it is safe when used properly.

The supplier also has an obligation to provide information about how the system is to be used to ensure health and safety.

The supplier should provide installation instructions to the installer, including as a minimum:

- details about the supporting structure - member sizes, material type and strength

- maximum guardrail post spacing

- connector details (i.e. bolting, screwing or clamping method).

The supplier should obtain information from the truss supplier about stiffening required to withstand additional loads.

Installers

Installers have an obligation to:

- install the system in a way that it is without risks to a person’s health and safety

- ensure that nothing about the way the system was installed makes it unsafe and a risk to a person’s health and safety when used properly.

To meet these obligations, the installer of the system should:

- ensure they have the appropriate competencies (through training, qualification and/or experience) to install the system

- follow the manufacturer's and/or supplier's instructions

- provide written verification about the system at handover to the person being supplied the system

- where there is a risk of a fall greater than 3 metres, a safe work method statement (SWMS) for high risk construction work is developed

- for a construction project, provide a copy of the SWMS to the principal contractor.

Handover information should include written verification that:

- the guardrail system and supporting structure are structurally adequate (e.g. verification by a suitably qualified engineer)

- the guardrail system has been installed in accordance with the supplier's instructions.

A person being supplied with the system, such as a principal contractor, employer or self-employed person, has obligations to ensure health and safety in the workplace. They should take reasonable steps to ensure the guardrail system can be used safely.

Users

Users should:

- obtain verification about the system from the installer

- have written information on verification of the system available on site.

- provide workers with advice received from the installer on the safe use of the system

Users have an obligation to:

- comply with the instructions provided about the safe use of the system

- not interfere with or misuse the system

- not alter or change the system in any way that may affect the safety of users of the system

- notify their employer or the principal contractor if the system is altered or damaged in any way

- develop a SWMS for high risk construction work where there is a risk of a fall greater than 3 metres

- for a construction project, provide a copy of the SWMS to the principal contractor

A principal contractor’s WHS management plan must include arrangements for the collection and any assessment, monitoring and review of SWMS for high risk construction work.

Further information

AS/NZS 4994 (set): Temporary edge protection

Managing the risk of falls in the workplace– Code of Practice

Managing the risk of falls in housing construction - Model Code of Practice – Safe Work Australia

Safe work on roofs information sheet – Safe Work Australia

Safe Work Method Statement (SWMS) for high risk construction work

Roof edge protection fact sheet - SafeWork NSW

Acknowledgements: SafeWork SA would like to thank WorkSafe Queensland for the base source of information.