10 May 2024

A recent near miss has highlighted the dangers of using unsecured lifting jibs on forklifts.

A worker narrowly escaped being hit by a load of steel when the lifting jib, which was incorrectly attached to the tynes of a forklift, slipped off and landed on adjacent machinery causing damage.

A SafeWork SA investigation identified a number of issues, including that the safety jib’s securing chain was missing, lack of training and poor communication between workers.

SafeWork SA subsequently issued the business with a number of statutory notices.

SafeWork SA reminds businesses to inspect lifting jibs for damage before use and ensure they are correctly secured to the forklift in line with the manufacturer’s recommendations.

Safety solutions:

- Lifting jibs should be checked and secured by a suitably competent person who has the knowledge and skills to perform the task

- Safety fittings must be used to minimise the chances of a lifting device falling

- Workers should be trained in communicating in a noisy environment

- Lifting plans should be available to workers to determine whether lifting techniques are adequate

- Where the lifting attachment’s lifting point is outside the forklift’s centre of gravity or the load is suspended, ensure the forklift’s lifting capacity is reduced to minimise overloading the forklift

- Lifting attachments must be used and maintained according to the manufacturer’s requirements.

Businesses are encouraged to review and revise their processes for lifting and suspending loads with forklifts.

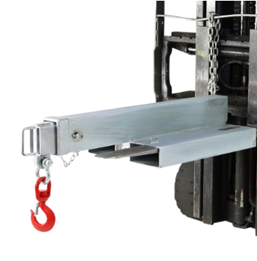

Examples of lifting jibs (L: Telescopic Short Jib R: Forklift Tine Hook).